For a period during the last few years, a shortage of paper propelled the supply chain issue to the top of print industry headlines.

During that time, the difficulty finding enough paper to meet customer demand was not the fault of any individual company but resulted from turbulent economic conditions caused by the pandemic. Fortunately, the worst of the shortage seems to have passed. Although many companies are still working through large inventory volumes purchased when supply was tight.

What is Supply Chain Management?

For print operations, there are a number of strategic and tactical steps a company can take to lower costs, improve quality, and reduce lead times.

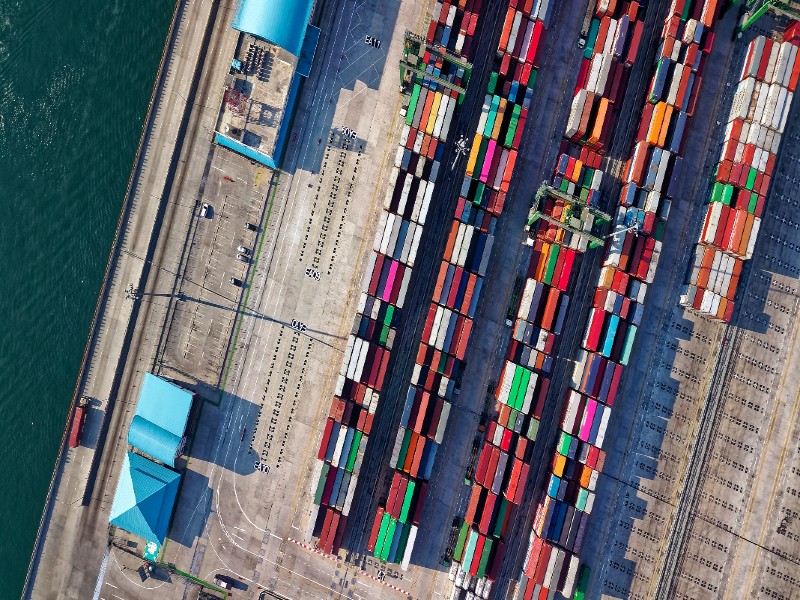

A supply chain is a network of individuals and companies who are involved in creating a product and delivering it to the consumer or end user.

For printers, the supply chain might begin operating when a business receives an order from a customer. It may also begin as the result of forecasted business.

The components of a supply chain include vendors, purchasing, warehouses, manufacturing operations, transportation companies, distribution centers, customers, and consumers.

The 6 key steps in a supply chain include:

- Planning the inventory and manufacturing processes to ensure supply and demand are adequately balanced.

- Manufacturing or sourcing materials needed to create the final product.

- Assembling components and testing the product.

- Packaging the product for shipment or holding in inventory until a later date.

- Transporting and delivering the finished product to the distributor, retailer, or consumer.

- Providing customer service support for returned items.

Supply chain management is a crucial process because an optimized supply chain results in lower costs and a more efficient production cycle.

Strategic Activities

Reduce the number of materials consumed in each product group. For example, minimizing the number of paper grades and sizes will result in improved productivity in all steps of production.

Reduce the number of suppliers used in each product group. Look for the ones that provide the most reliable delivery and quality.

For example, a company manufactures high end cosmetic packaging and a supplier provides UV coatings. The coatings need to perform during the application process and be durable. They must meet the design and quality specified by the manufacturer, and they must work as intended.

A reliable supplier will fill the manufacturer’s order on time and with consistent quality.

Tactical Activities

Here are some of the best practices that are seen in successful supply chain management systems:

- Support continuous improvement.

- Aim for increased velocity. That is, reduce the time it takes for materials to move through the supply chain.

- Encourage collaboration among the individual businesses in the supply chain.

- Seek new technologies that improve processes.

- Have metrics in place that allow employees to measure the success or failure of each step in the supply chain.

A well-managed supply chain will reduce production costs, improve quality, and reduce lead times. All these will result in improved profitability and happier customers.

If you’re looking to improve your supply chain management, contact us. Our experts are here to help.

By Ken Freek

——-

Ken Freek is the Business Improvement Specialist at Connecting for Results. He is an industry veteran with significant experience in marketing, operations, automation, change management, supply chain and logistics. Ken is a recognized and successful team leader who uses a solutions-oriented approach to business challenges. He has demonstrated the ability to quickly learn and use new skills and technologies. To get in touch with Ken, contact us.